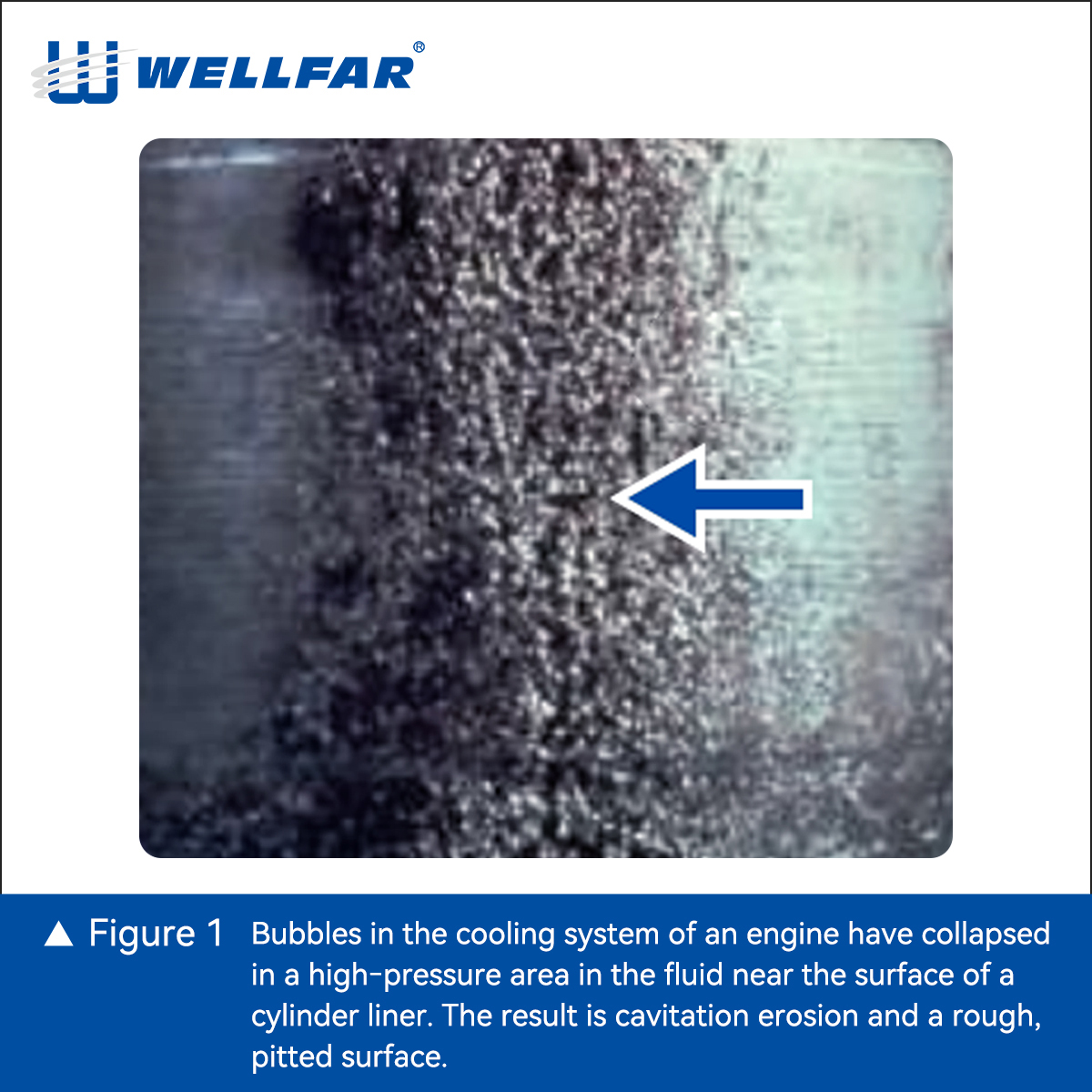

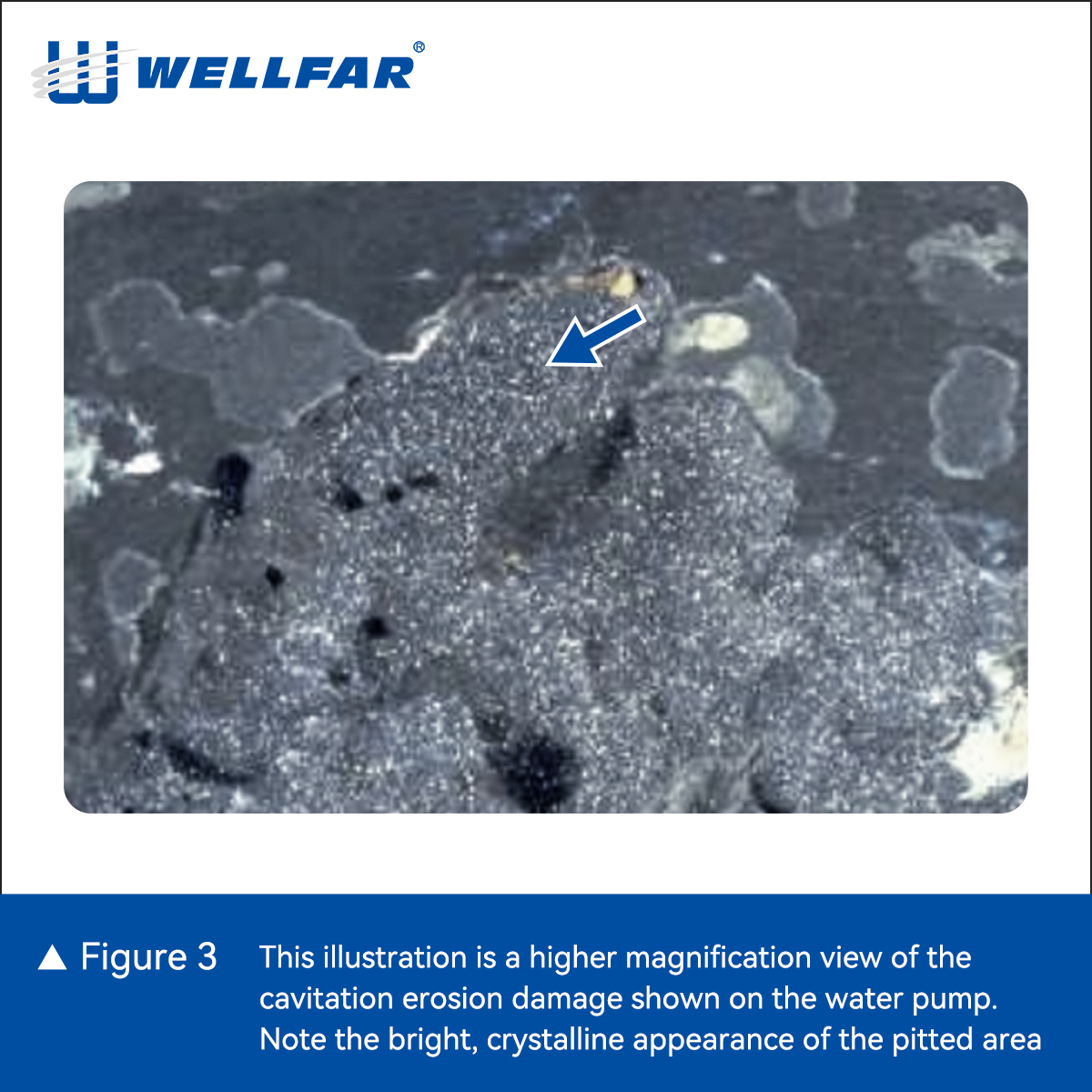

Cavitation erosion wear is pitting damage that results when bubbles collapse and the fluid stream that had been supported by the bubble impacts the part surface. Two things are required for cavitation erosion wear to take place: bubbles and an area of increasing pressure capable of collapsing (imploding) the bubbles. Bubbles can form in a fluid as a result of an air leak or as a result of a low-pressure area that releases dissolved gasses or vaporizes (boils) the fluid. High-pressure areas generally result from the design or operation of a system. If the material being damaged by cavitation erosion is susceptible to corrosion by the fluid, then the processes of cavitation erosion and corrosion may work together to accelerate damage. Cavitation erosion produces a clean surface that is more likely to corrode. So, in operation the surface corrodes, cavitation cleans off the corroded material, the surface corrodes again, and the process repeats itself. When cavitation erosion occurs, the following road signs may be observed: 1.Irregular shaped surface pits and holes in the damaged area, possible narrowing toward one end. 2.Pitted surfaces with a rough and crystalline appearance (brittle fractures from fluid impact.) 3.Self-generated, secondary debris particles – may also produce abrasive wear damage. 4.In some systems, such as pumps, there may be a noticeable change in sound during operation.

Cavitation Erosion Wear

2025-12-23 01:59