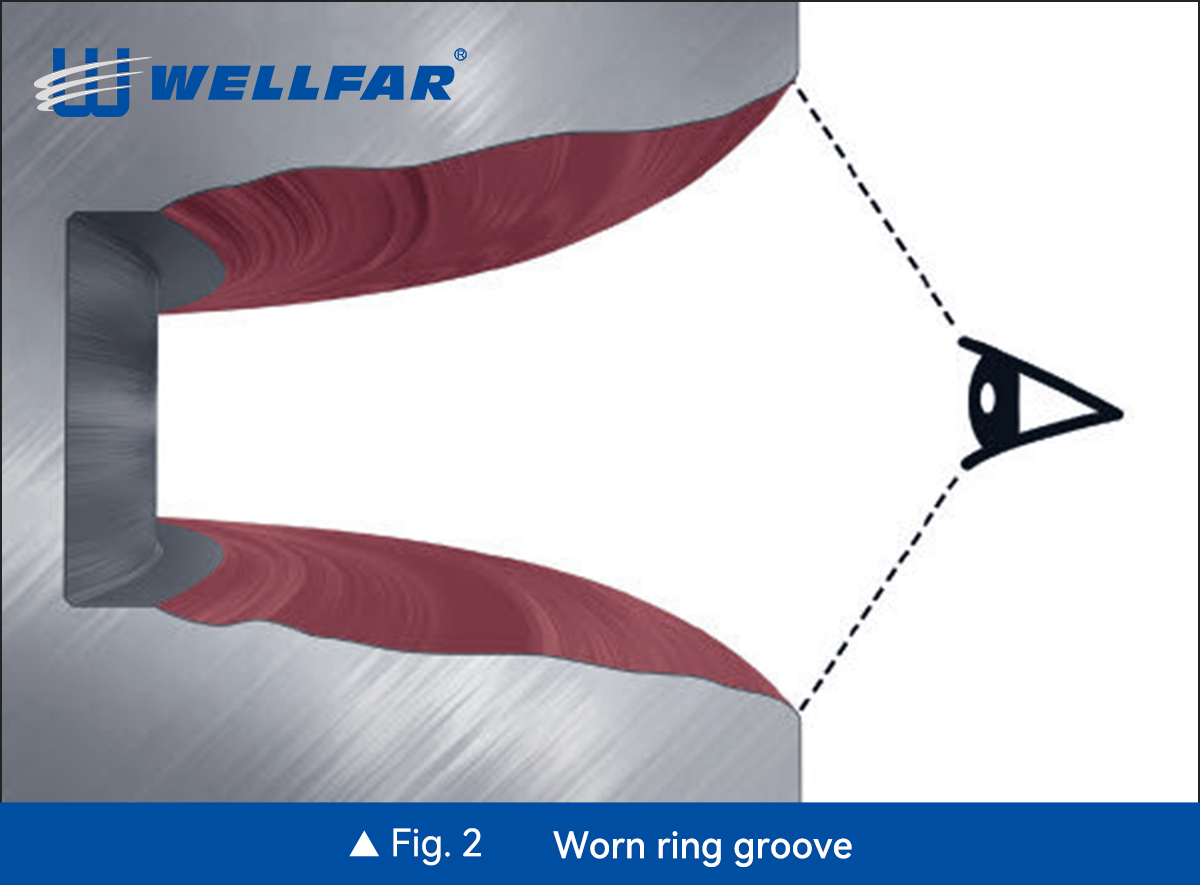

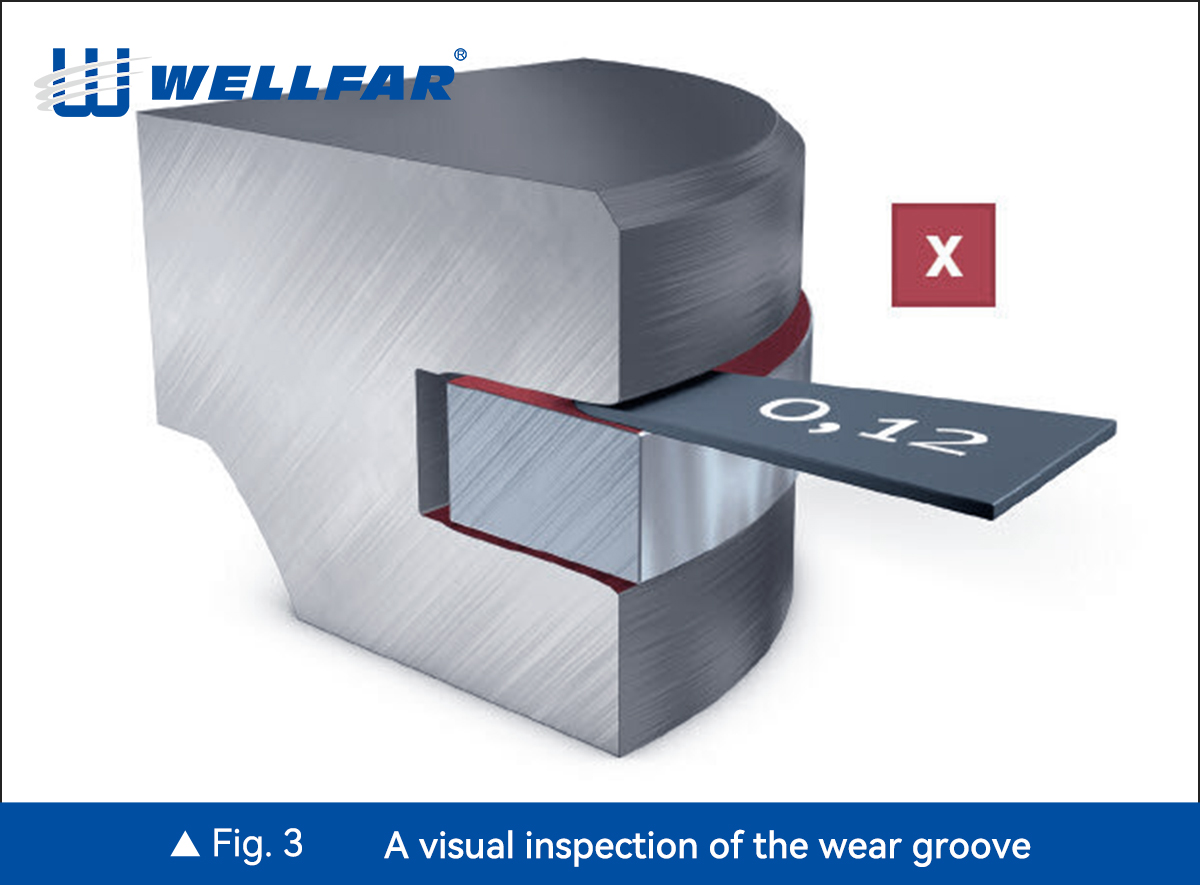

If new piston rings are to be pulled on to pistons that have already been run in, the ring height clearance determines whether the piston can be reused. Axial clearance is typically checked by inserting a feeler gauge between the ring and the top of the ring groove. A slight drag will indicate the proper clearance. Start with the minimum of 0.025 mm and work up. Don’t measure between the ring and the bottom of the ring groove as you might damage the sealing surface. Some builders measure the groove itself with a stack of feeler gauges and then compare it to measuring the ring thickness with a micrometer. The first method is preferred and it is good practice to check it at several places around the perimeter of the piston. The relevant piston ring is inserted in the cleaned ring groove as shown in Fig. 1 and measured with a feeler gauge. If a new piston ring is to be measured in a run-in piston, the method shown in the figure is better than mounting the piston ring on the piston. Pulling the piston ring repeatedly on and off the piston may cause material deformation on the piston ring, which impairs the function. The wear dimension refers to the outer edges of the ring groove to be measured, i.e. it must not be possible for the feeler gauge with a thickness of 0.12 mm to be pushed between the piston ring and ring groove as shown in Fig. 2. In this case, the ring groove is classed as already worn. Ring height clearance (mm) Suitability of the piston 0.05-0.10 Pistons can be used 0.11-0.12 Increased caution is required > 0.12 Piston is worn and has to be replaced It is not possible to check the ring height clearance on keystone rings in pulled-on and un-tensioned state. Due to the keystone shape, the correct ring height clearance is only achieved in the keystone groove if the piston ring is pressed together on the cylinder dimension or mounted in the cylinder.

This means that a measurement is difficult. For this reason, the inspection must be restricted to a visual inspection of the groove for wear (Fig. 3).

Measurement And Assessment Of Ring Grooves

2025-02-07 18:45