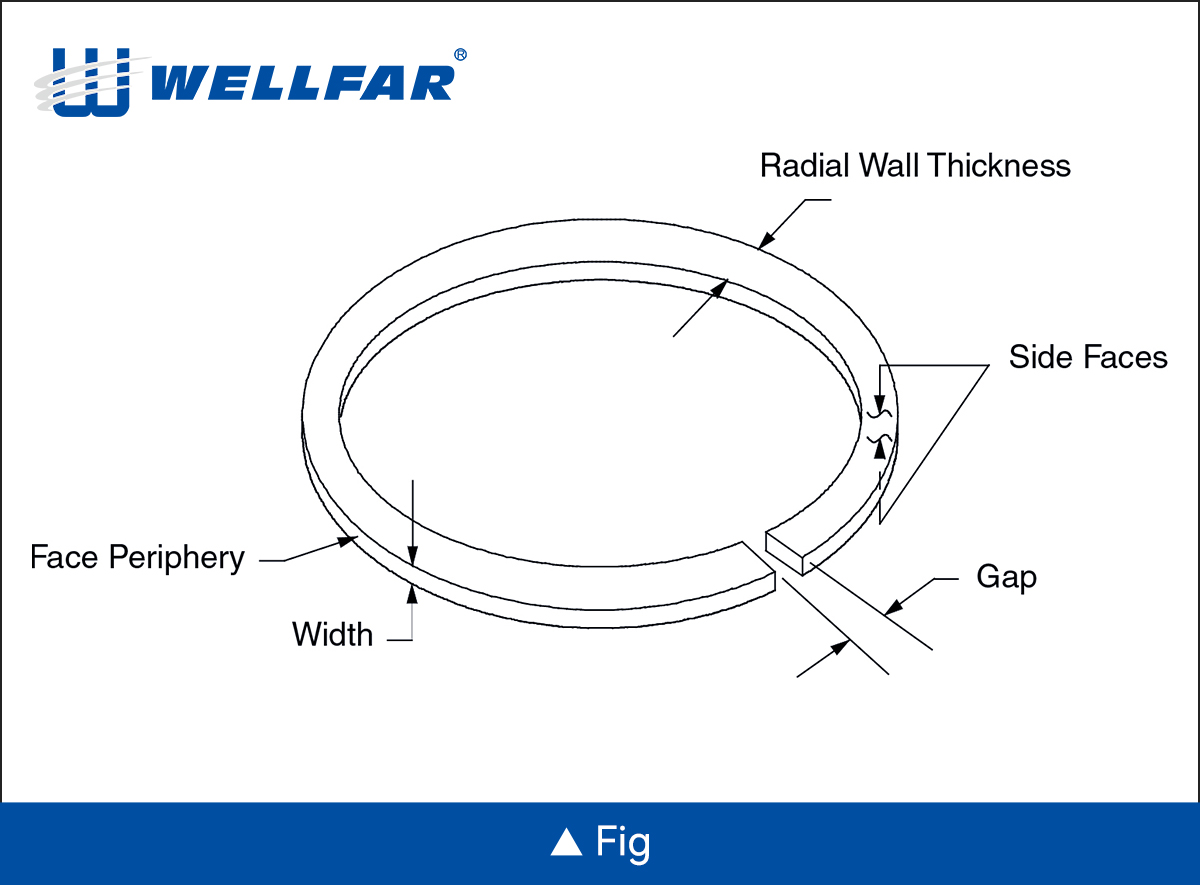

Recent years there is tendency to change the ring material from a grey cast iron top ring to a carbon steel top ring. The advantages include; 35% more strength, 30% less weight and double the resistance to side wear which is a common problem on late-model engines. Since the steel is 35% stronger than cast iron, we can achieve the same ring tension with 35% less weight. That weight savings is made by reducing the radial wall thickness of the steel ring. The net result is a ring that's lighter, so it has a higher effective RPM potential, stronger - so that it weathers the abuse of today's high output engines better, and actually seals better because the reduced radial wall allows it to conform to the cylinder wall better. As for back clearance - that area behind the ring which is calculated by subtracting the ring radial wall width from the root depth of the ring groove in the piston. For example; if I have a ring radial wall of .170” and a groove depth of .195” then my back clearance is .025”. Reducing the radial wall of the replacement carbon steel rings does increase the back clearance because they are going into piston grooves designed for the thicker radial wall of the cast iron rings. For optimum performance, ring back clearance should be minimized. This comes from the fact that the top compression ring needs the pressure from the combustion gases to get in behind the ring and push out on the ring to maintain proper seal on the high pressure, or combustion stroke. The logic was that the smaller the area created by the back clearance, the quicker that pressure would build to push out on the ring, and the quicker the ring would react to its sealing requirements job. That logic is all good but what about the reality of the concept?

Ring Material Change And Importance Of Ring Back Clearance.

2025-02-25 09:55