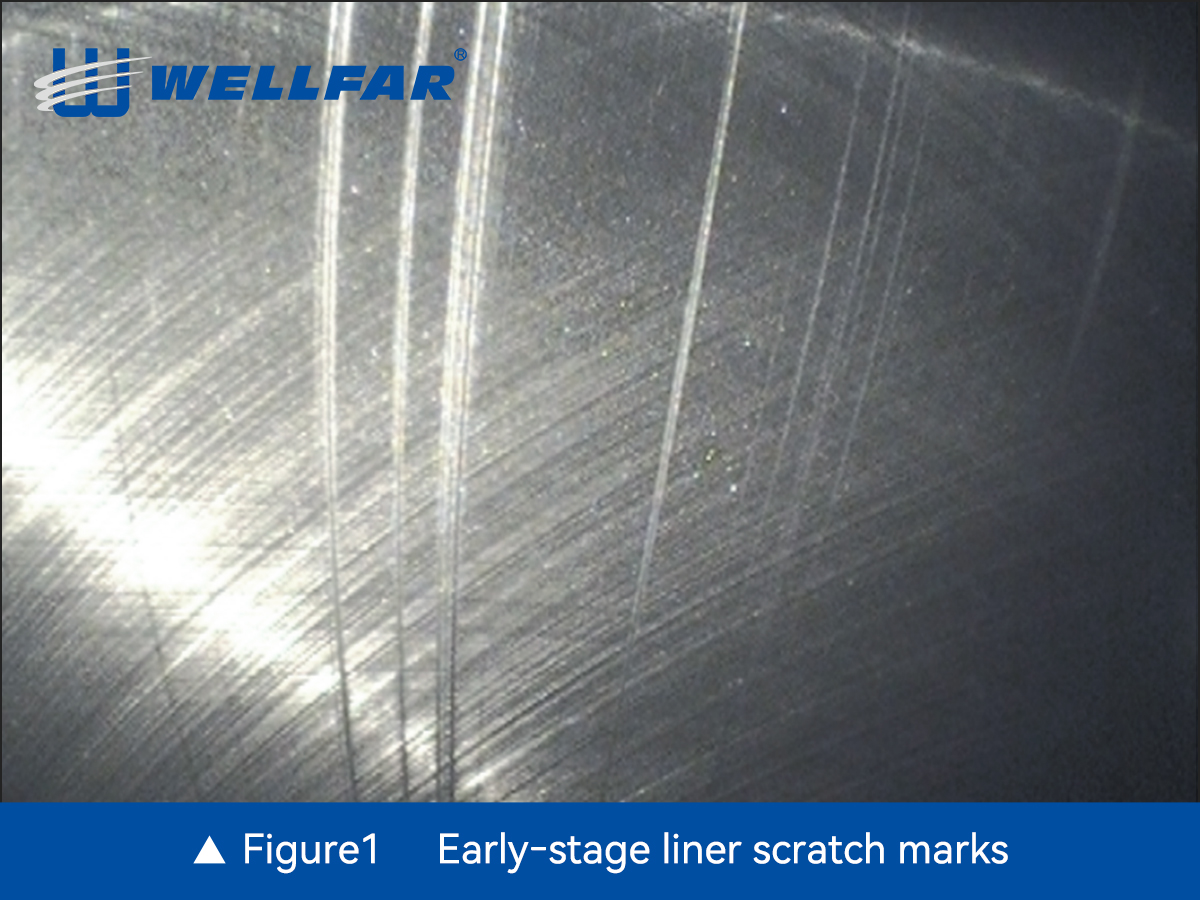

Scratches on liner is a very common failure type, which can lead to severe issues, such as increased oil consumption, loss of compression, and accelerated wear on the piston rings. Late-stage failure can be found by decreased engine power, high blowby or abnormal noise. But early-stage liner scratch is difficult to catch. Below is picture of diesel engine liner run only less than 100 hours, found by regular check, photo by endoscope. This kind of scratch can deterioration very quickly, grooves may grow deeper, rings may break, piston maybe welded with liner or seized. Root cause of this kind of failure can be various, below are some high potential root causes: a) Foreign Particles (Abrasive Contaminants) ▶Symptoms: Deep or random scratches, excessive liner and piston ring wear. ●This may cause by dirt, dust, or metal debris in the cylinder during assembly, in this case, the failed liner can be random, like #1, #4, or ●ther very random combinations. ●Inadequate air filtration allowing contaminants into the combustion chamber. This kind of failure usually cause such cylinders which is close to each other and closer to manifold, in most cases, #3, #4 cylinders. oContaminated oil (poor filtration or improper maintenance). b) Improper Lubrication ▶Symptoms: Dry contact marks, scoring, or rough patches. Which might be caused by: ●Low oil pressure or insufficient lubrication reaching the liner. ●Use of poor-quality or incorrect viscosity oil. ●Oil degradation due to overheating or contamination. c) Piston Ring Issues ▶Symptoms: Vertical scratches matching piston ring travel. After disassembly, below can be found: ●Worn, broken, or incorrectly installed piston rings. ●Excessive ring tension causing aggressive wear. ●Improper honing pattern on the liner, leading to oil starvation. d) Assembly Errors ▶Symptoms: Inconsistent scratch patterns or damage after installation. Such as: ●Mishandling of liner or piston during installation. ●Incorrect liner seating leading to misalignment.

Early Stage Liner Scratch

2025-04-30 10:50