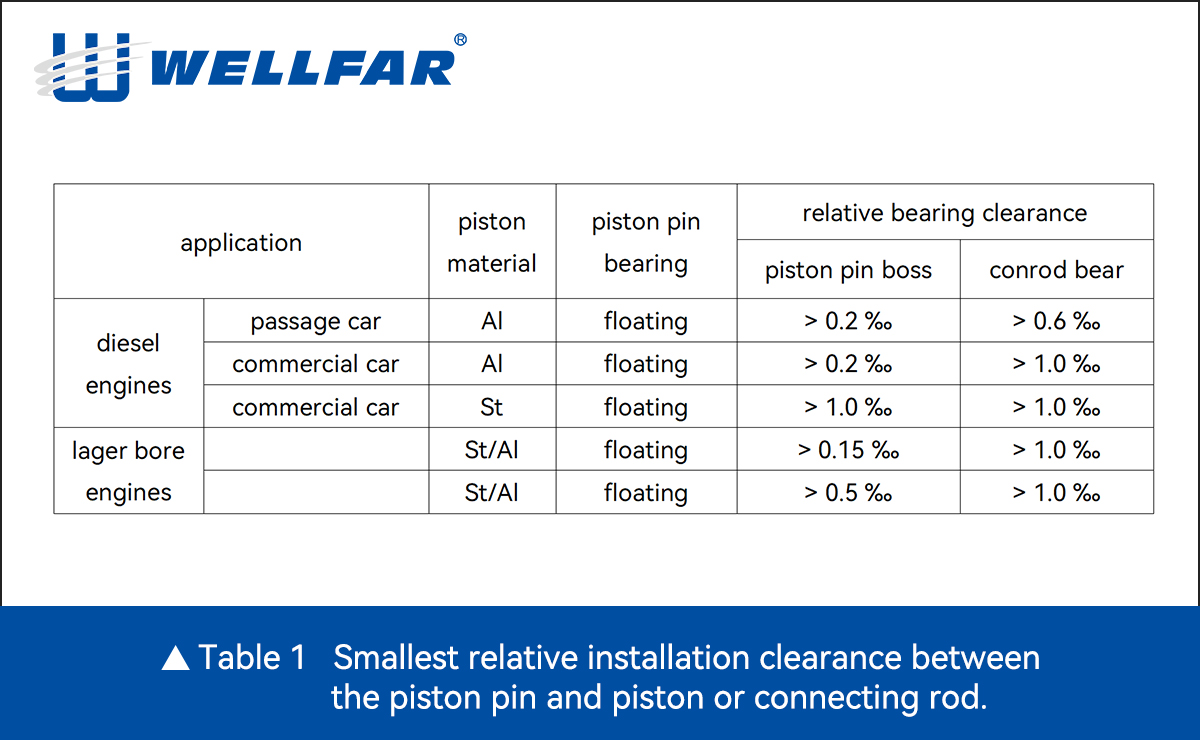

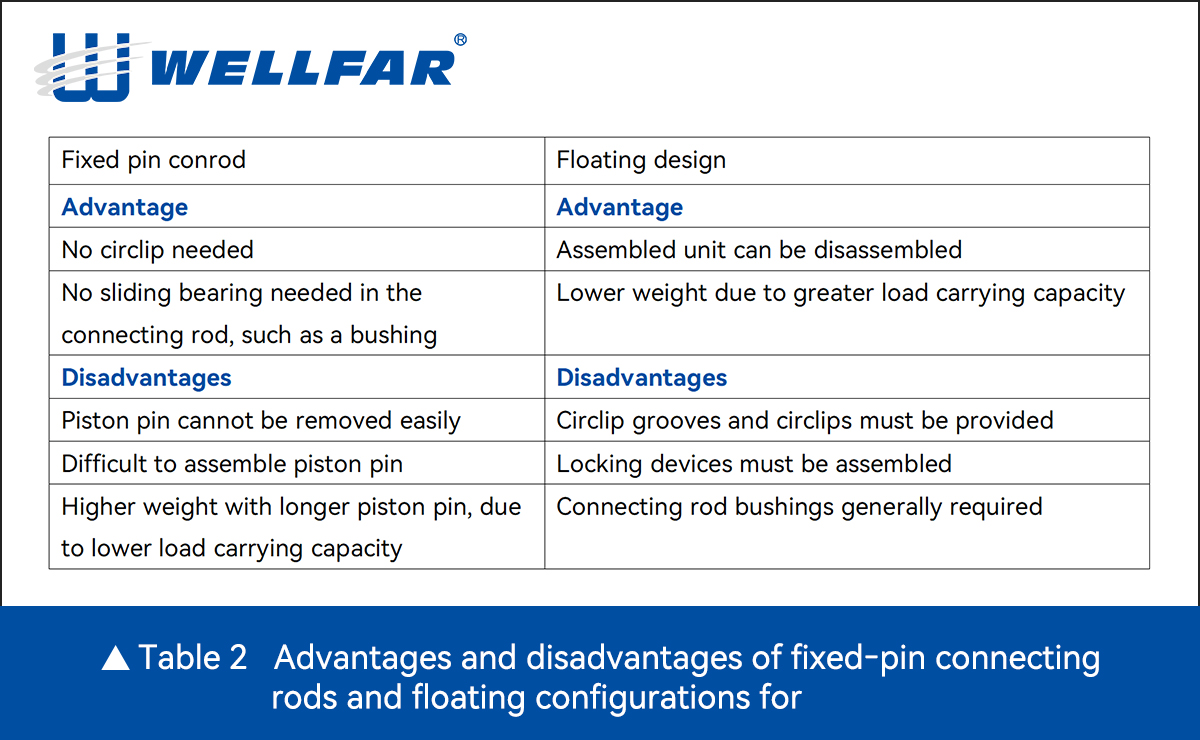

Piston pins are designed for loading by gas and inertia forces, contact pressure, and deformation. The bearing clearance between the piston pin and the piston pin boss and small end bore must also be determined, in order to ensure trouble-free operation, that is, quiet piston action and minimal wear. Consideration must be given to the fact that when the thermal expansion of the piston–piston pin–connecting rod system varies, the clearance can be larger than the installation clearances for a warm engine and smaller at cold temperatures. The temperature dependence of the bearing clearance between the piston pin and small end bore is generally disregarded. When designing the smallest relative bearing clearance in aluminum pistons (Table 1) in some engines, differentiation must be made between a “floating” pin bearing and a piston pin with a shrink fit in the small end bore. A piston pin with a floating configuration is the standard design and is the variant that can be loaded the most specifically in the piston pin boss. With the shrunk connecting rod design, the piston pin is seated in the small end bore with some overlap. Advantages and disadvantages of fixed-pin connecting rods and floating configuration of the piston pin in the connecting rod are shown in Table 2.

Piston Pins Dimensioning And Floating Design

2025-03-10 18:10