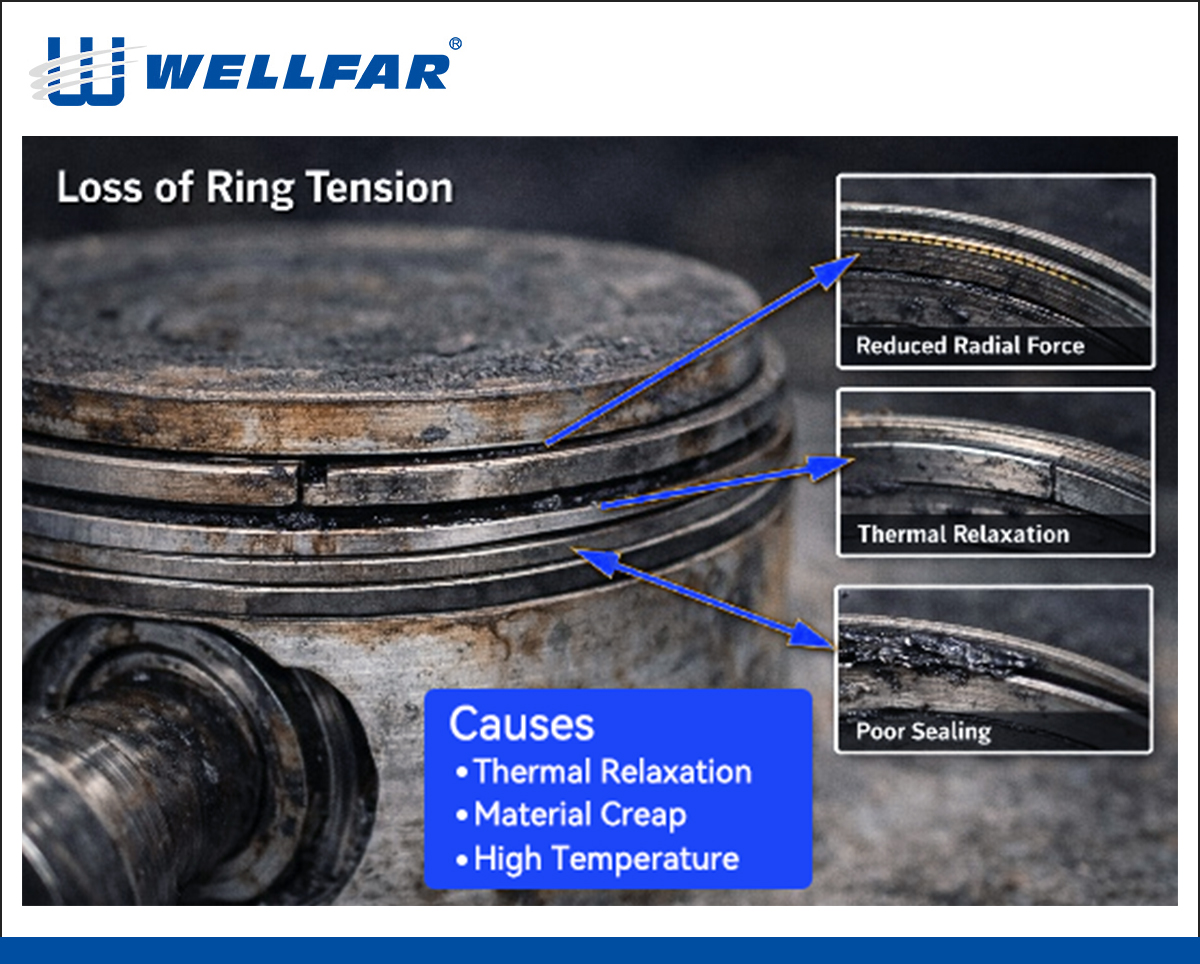

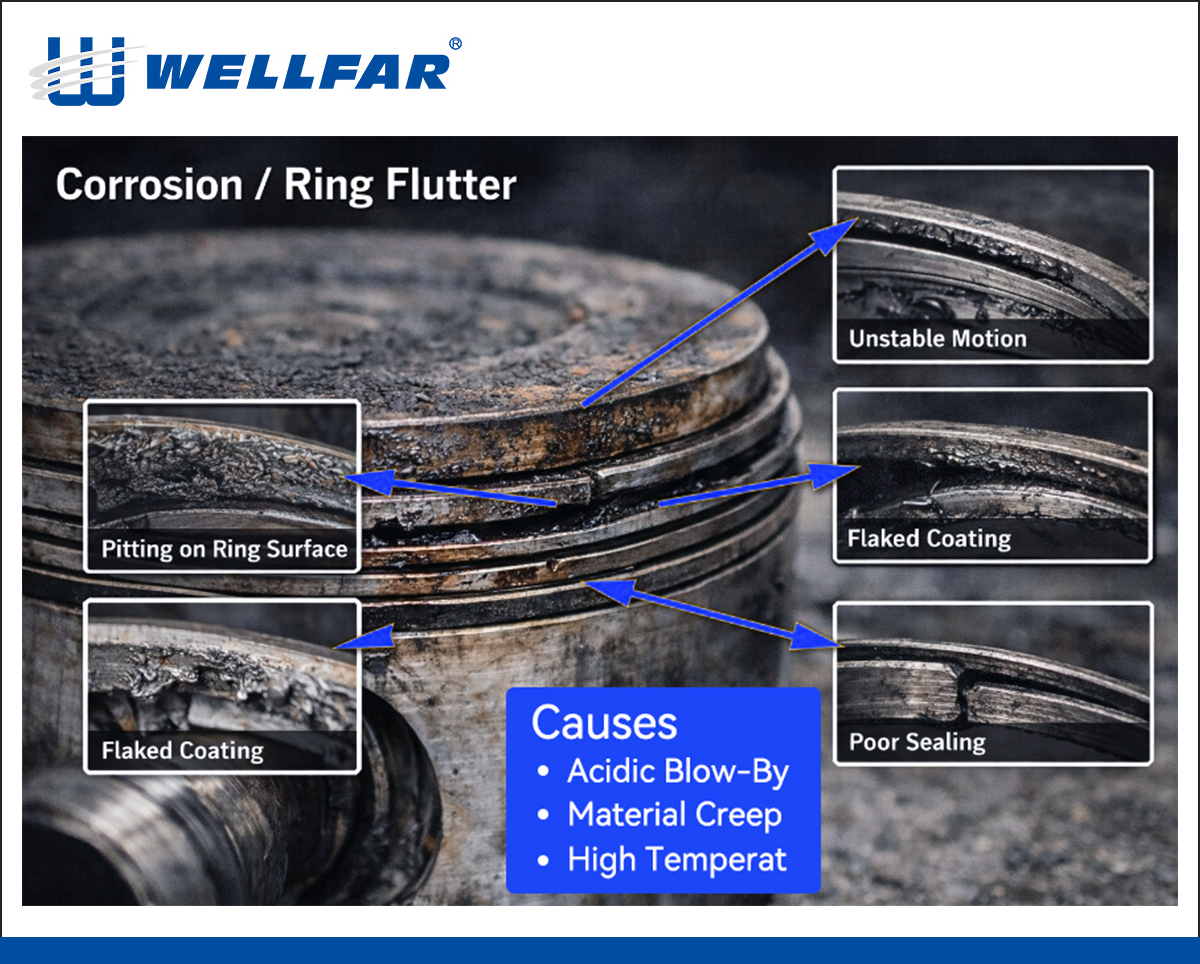

Ring breakage / cracking mainly affects the top ring and is driven by excessive thermo-mechanical loading. High peak cylinder pressure, abnormal combustion, or rapid thermal gradients can cause brittle fracture, especially if ring end-gap is insufficient and thermal butting occurs. Mechanical contributors include bore distortion, excessive groove clearance, and low-toughness materials. Symptoms are sudden compression loss, high blow-by, and liner damage. Countermeasures include larger end-gaps, steel or ductile iron rings, and tougher PVD coatings. Excessive ring wear occurs across all rings and is typically abrasive or corrosive. High soot loading, dust ingestion, poor oil filtration, and acidic blow-by accelerate face wear and reduce sealing capability. Design factors such as high contact pressure and incompatible ring–liner material pairs also contribute. Symptoms include gradual power loss, rising oil consumption, and increased blow-by. Wear-resistant coatings, improved liner honing, and better soot control are key mitigations. Scuffing and micro-welding result from oil film breakdown under high load and temperature. Oil starvation, rough liner surfaces, excessive ring pressure, and incompatible coatings promote adhesive wear and local material transfer. This often occurs during high-load, low-speed operation or cold starts with high fueling. Rapid liner damage and sharp oil consumption increase are typical indicators. Countermeasures focus on low-friction coatings, improved oil control, and enhanced piston cooling. Ring sticking (carbon packing) is caused by carbon and oil deposits locking the ring in its groove. High groove temperatures, oil coking, incomplete combustion, and high-ash oils are common drivers. This leads to loss of sealing, high blow-by, poor starting, and oil consumption. Anti-carbon coatings, improved cooling, and optimized oil formulations reduce risk. Loss of ring tension arises from thermal relaxation, creep, or wear, especially in cast iron rings under sustained high temperature. It results in progressive blow-by and poor compression. Steel rings with higher thermal stability are preferred. Corrosion and ring flutter are secondary but important. Acidic combustion products cause pitting and coating failure, while dynamic instability at high speed leads to intermittent sealing loss. Both require careful material selection and groove/ring dynamic optimization.

Disel Engine Piston Ring Failure Mode Analysis

2026-02-10 01:25